Tools Every Watch Enthusiast Should Have: Part 1

As a watchmaker, one of the most common questions I get asked is, “What are the best tool kits to get?” The answer has two parts, the first, don’t buy a pre-made tool kit because the tools in them are generally junk. You risk damaging your more expensive watch or just having a tool that falls apart entirely. Sometimes they have a piece or two that’s good, but it’s always better to buy it alone. So don’t buy a tool kit, buy the tools individually. This way, you can get high quality tools (the first time around) and have a kit that is tailored to your needs and operations.

Then people ask, “Can you make me a tool kit?” this question also has two parts. The first, no, I cannot. I get asked this so often that creating tailor made kits for everyone who asked would soon become a full time job, but one where I don’t get paid. The second part is, I see it as a rite of passage. If you’re going to be working on your watch you’re going to need to be persistent, patient, and resourceful-if finding watchmaking tools on the Googles is too challenging, you’re gonna have a bad time when you get to your watch.

Where are we left when we’ve gotten past that point? There are lots of options for tools. You know what tools you need but you’re hamstrung by the choices. Expensive ones aren’t always good, cheap ones aren’t always bad-but the only way to find out is to buy them and find out. Luckily for you, I’ve used a lot of tools. For this guide, we’ll work our way up from the most basic tools which also happen to be some that you’ll use the most frequently-as a watchmaker or a hobbyist.

THE SPRINGBAR TOOL. I can assure you that over the years I have been through many, many springbar tools. Many of them had me saying things like, “what is this garbage?” or “the fuck is this? I can’t believe Bergeon actually made this!” or even, “yes, I use an $0.83 Chinese made springbar tool.”

What you’ll see next are the tools that don’t make me irrationally angry, that are quality, and are the end product of years of selective watchmaking forces.

The Bergeon 7767 is the best generalist springbar tool. Solid stainless construction. Tips that are threaded and replaceable (which means you can swap them for different styles as well). A proprietary knurl pattern that makes it comfortable and grippy. The 7767 configuration comes with a ‘fork’ tip that’s good for gripping and compressing shoulders and flanges. The other side is a cylinder with a divot in the end. This is good for compressing springbars from the tip as well as poking through drilled lugs. It’s also affordable, you can find it for $15-$20 most places and is absolutely worth it. Also Bergeon isn’t paying me to do any of this, so just a heads up, that their special ETA 2892 movement holder that costs like $250 has a slot that isn’t wide enough to accommodate the 2892 stem when it’s in the time set position. So yeah, Bergeon, still waiting to hear back about that. I will give Beco Technic a shout out for excellent product selection and excellent customer service.

Next up is the Bergeon 7825, the springbar tweezers. There are similar ones and similar styles. You don’t want them. You want the 7825, the tweezers. They’re pricey, but for high precision end links (brands like Rolex and Grand Seiko come to mind), they are absolutely necessary. Some brands even have end links or integrated straps that you actually cannot remove (within reason) without this tool. This will save you from making a mess of your lugs, especially with aforementioned brands (Rolex, Omega, Grand Seiko, etc)

It’s important to have something to put your case on when working on it so it doesn’t slip or get marked. This category is CASE CUSHIONS & CASE HOLDERS (not to be confused with movement holders). The principle is simple enough, and this category is a bit of a free for all. You can cheap out if you want case holder, an all plastic one isn’t bad because if something happens or you mount it wrong there’s not much of a chance the plastic will scratch your watch. For more advanced watchmaking the case holder doesn’t see tons of action (more proprietary and integrated to casing tools are preferred) but it’s like $2, it’s convenient and indispensable when it is the right tool.

Case cushions. The most common cheap ones are the leather ones, they’re fine and will get the job done. I got to a point where I splurged and got the gel Bergeon 5395-55. It’s absolutely worth it if you’re doing lots of watches or even changing straps a lot. It comes in a larger diameter if you’re a size queen and really want a big one. The base is tacky so it doesn’t slip and the gel has pretty excellent grip so your watch doesn’t slip. For me, this gets used every time I’m at my bench so I’ve certainly extracted the $30 value from it.

Fun fact: the notches cut away on the base of the case holder are so you can lock it in a vice!

Good screwdrivers are important in watchmaking. You’ll need some to remove screw pins from screw pin style bracelets. Cheaper screwdriver blades are generally softer steels, meaning they’re more prone to sheering and breaking under load. A full screwdriver kit is expensive (above is my Horotec set). Most shops will offer the ability to buy individual screwdrivers which is a good way to get the sizes you need (if you’re just using it for bracelets). Or if you’re really into saving money you can get cheap handles then buy replacement stainless steel blades. You wont go wrong with a set from Horotec or Bergeon. Common sizes for bracelet screw pins range from 1.2mm to 2mm. You should also use heat to break loctite before unscrewing your screw pins and reapply loctite when you’re done. Below is a brief 1.5 minute tutorial on sizing screw pin bracelets.

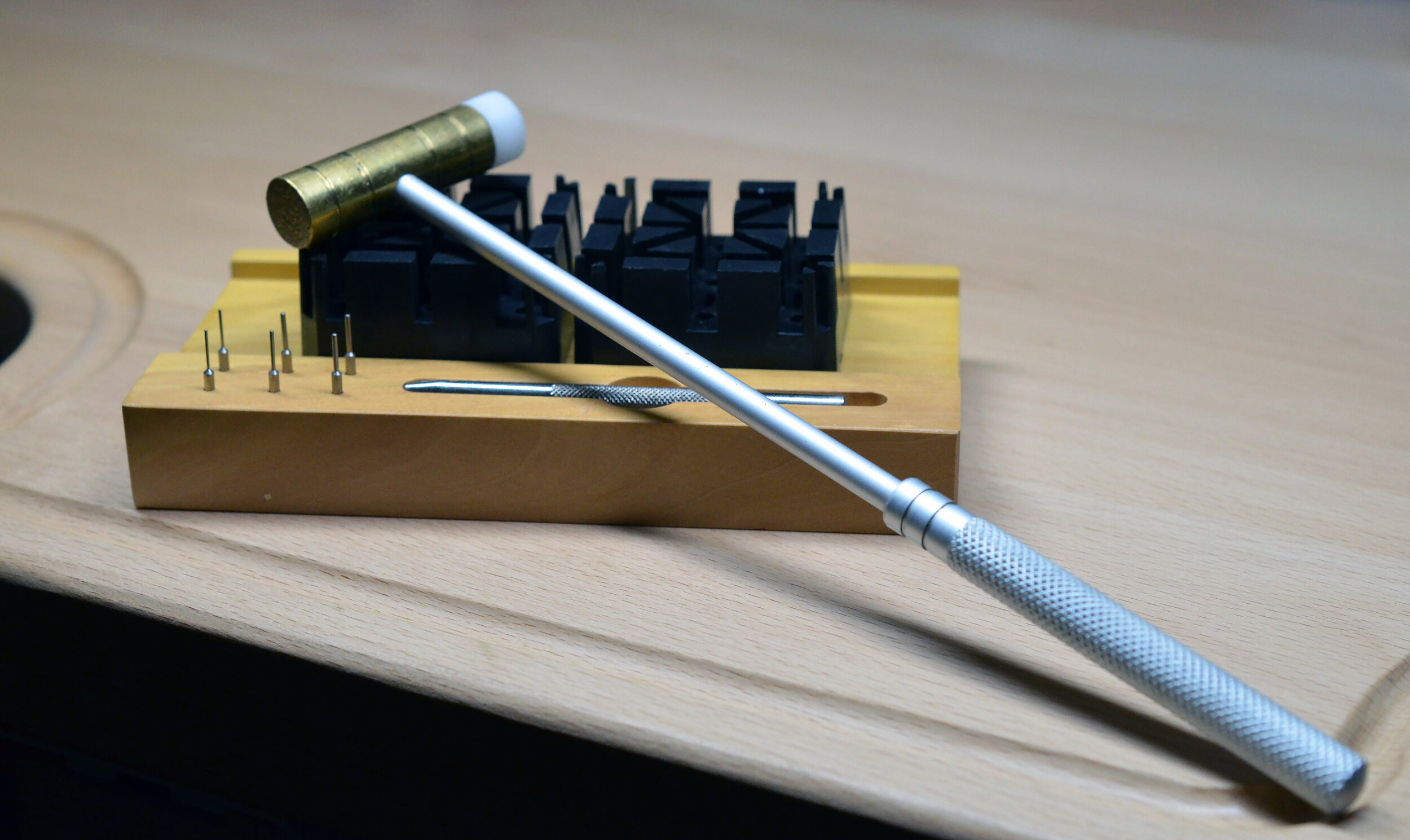

Here we have the champion of pin and collar bracelets. A bracelet block is another cheap but indispensable tool that makes resting and holding bracelets very simple. They’re also great for holding screw pin style bracelets. There are soft plastic ones you can pinch and there are hard plastic ones that are more rigid. Here I have a set that’s a wood base that holds the blocks and includes different sized pins and a little holder for them. It’s great. It’s simple. It works. And I think the set costs $10 or so. Deal.

The next part is the hammer grab a brass hammer with a plastic side. Not only is this good for hammering in & out pins (video tutorial below) but has many other uses down the line if you want to get into more 'watch stuff’.

This concludes part one of tools you should have. The next segment will continue to advance in complexity and address some other common, but more involved scenarios the watch enthusiast may find themselves in.

As always, likes, shares and subscribes are all excellent ways to support Orion (and I do appreciate it even if I can’t thank it each time). So if you enjoyed this content or something else on this blog, be sure to let a friend know!