Seamaster PLOPROF 1200M a review.

The strange and beastly Watch

The Omega Ploprof

Design lost to time.

The watch industry is full of watches, many plain designs, derivative designs, designs so good they barely changed since their introduction and the watches that are all slight variations on classics. The Ploprof harkens from a time when technology was limited and when watches were functional tools. To understand the Ploprof (Plongeur Professionnel, the French for professional diver, and abbreviated with the first few letters of each word PLO and PROF), we need to understand its history and the constraints of the time period.

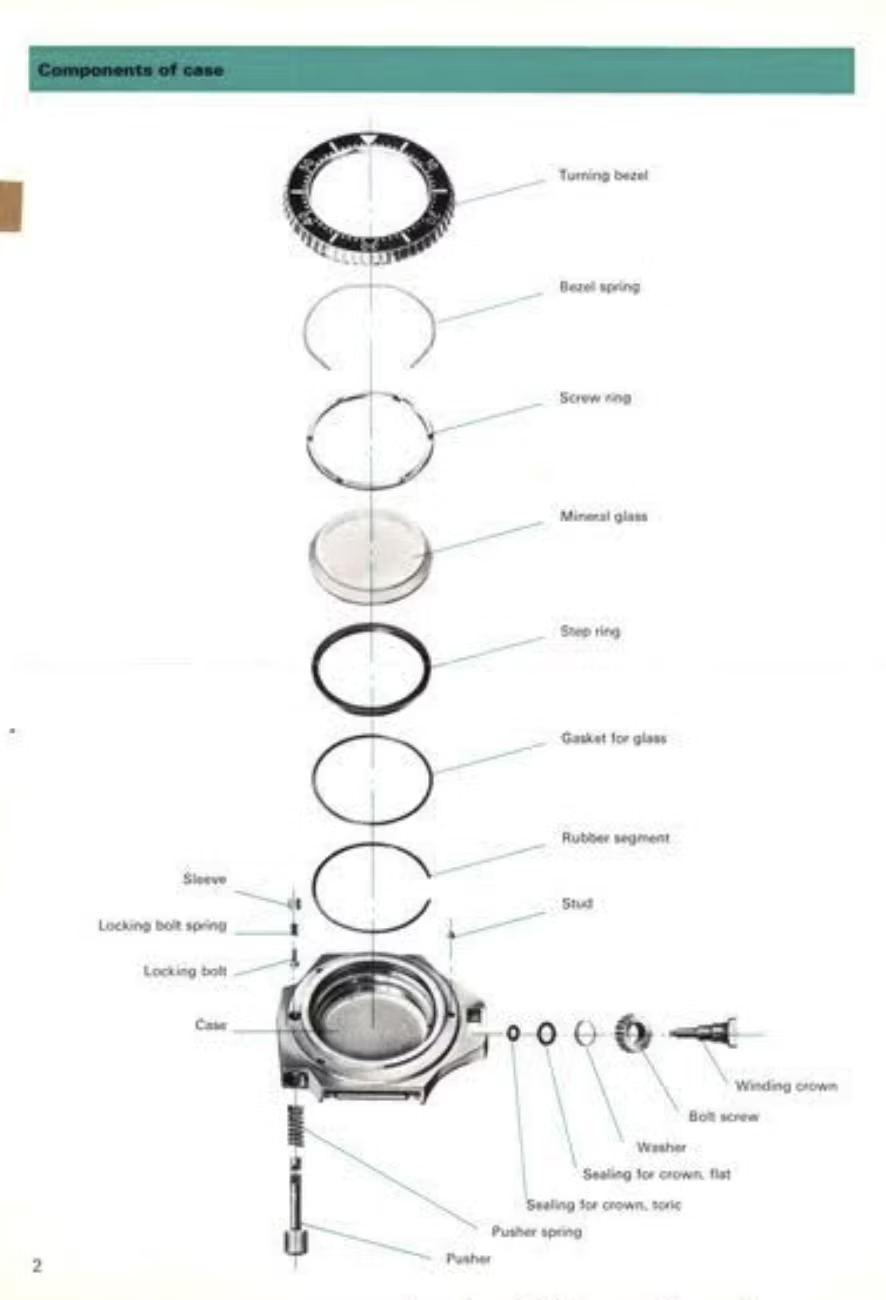

Exploded view of the case components of the original Seamaster ‘Ploprof’

The Ploprof is a dive watch from the time when deep sea environments and saturation diving was an emerging field. The mechanical watch, at this time, was a mission critical tool that divers relied on to visualize their oxygen reserves. In saturation diving, which is a form of diving that is hallmarked by deeper depth, diving bells and underwater environments where divers may live for the duration of their mission, the environment is under so much pressure that the divers need to breathe a mixture of helium and oxygen (heliox). The special gas mixture is because nitrogen, at high pressures, diffuses through your tissue and causes nitrogen narcosis (a condition which is extremely inebriating and causes disorientation and inability to think clearly or at all), which obviously means compressed air which a diver may use at shallow depth is not an option for the highest pressures. Helium does not have this narcotic effect, so it’s mixed with oxygen and pumped into dive bells and dive habitats. Helium, is the second smallest element and our divers of yesteryear are now sharing a space with helium under high pressure. The small atomic size of helium, combined with a high pressure environment meant that it could get between the, normally air-tight, gaskets of early dive watches. This would cause issues, as you could imagine, an example is during decompression the crystal or watch may pop apart since the inside of the watch was pressurized with helium. And thus, an issue presented itself for the watches (an important instrument back then) of saturation diving. They were no longer safe in pressurized environments combined with heliox. Since we are now looking back at history, we know that companies (Rolex and DOXA) developed the helium escape valve, a one way pressure relief valve, to prevent dive watches from popping apart. The HEV made its debut in 1969 (and the Ploprof in 1970) and while DOXA did co-create it, a pushy Rolex ended up with the subsequent patent.

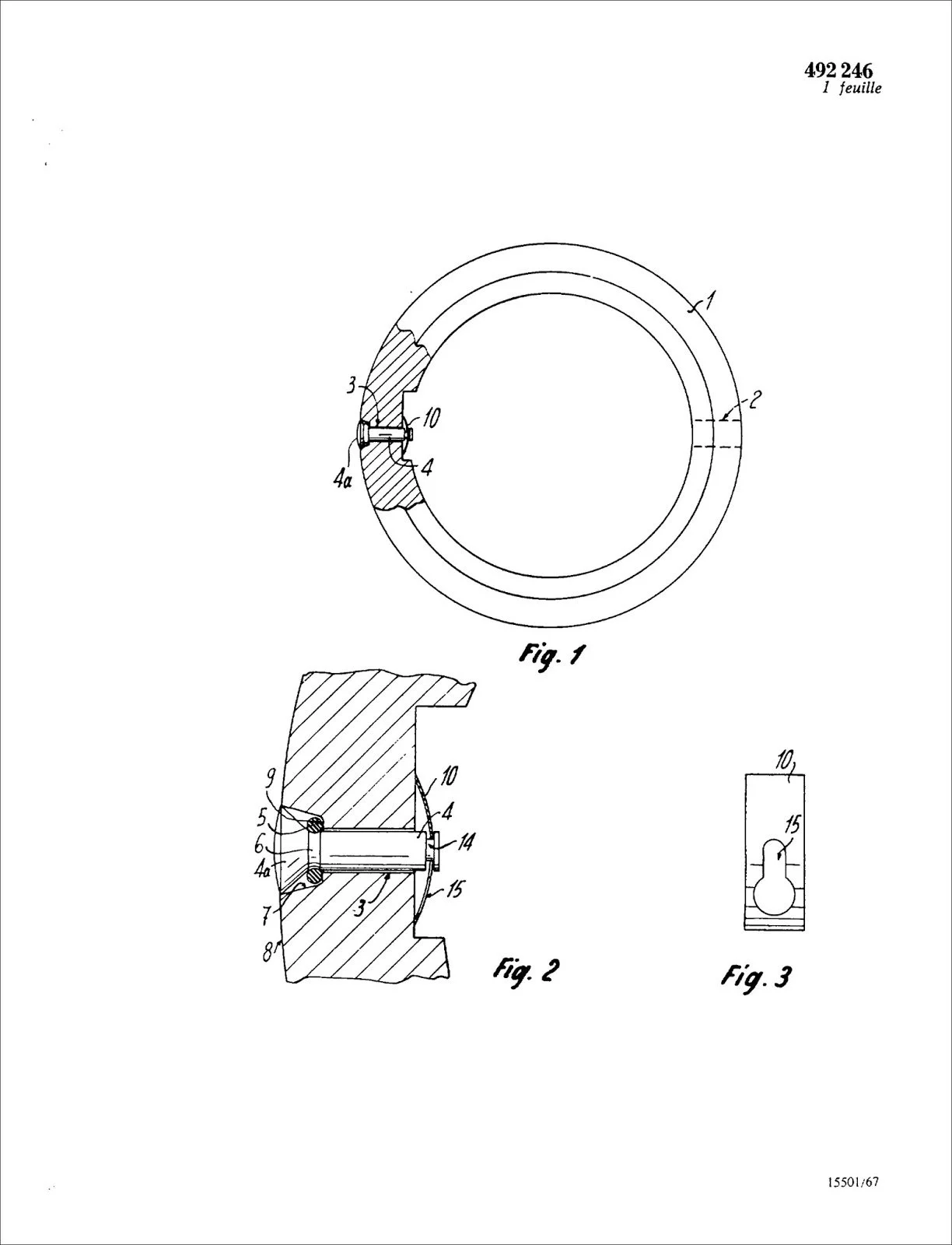

Rolex Helium Escape Valve

A page from the original patent for the HEV. You can see how a spring keeps it closed against the case (10) which gets pushed open when the pressure differential is high enough.

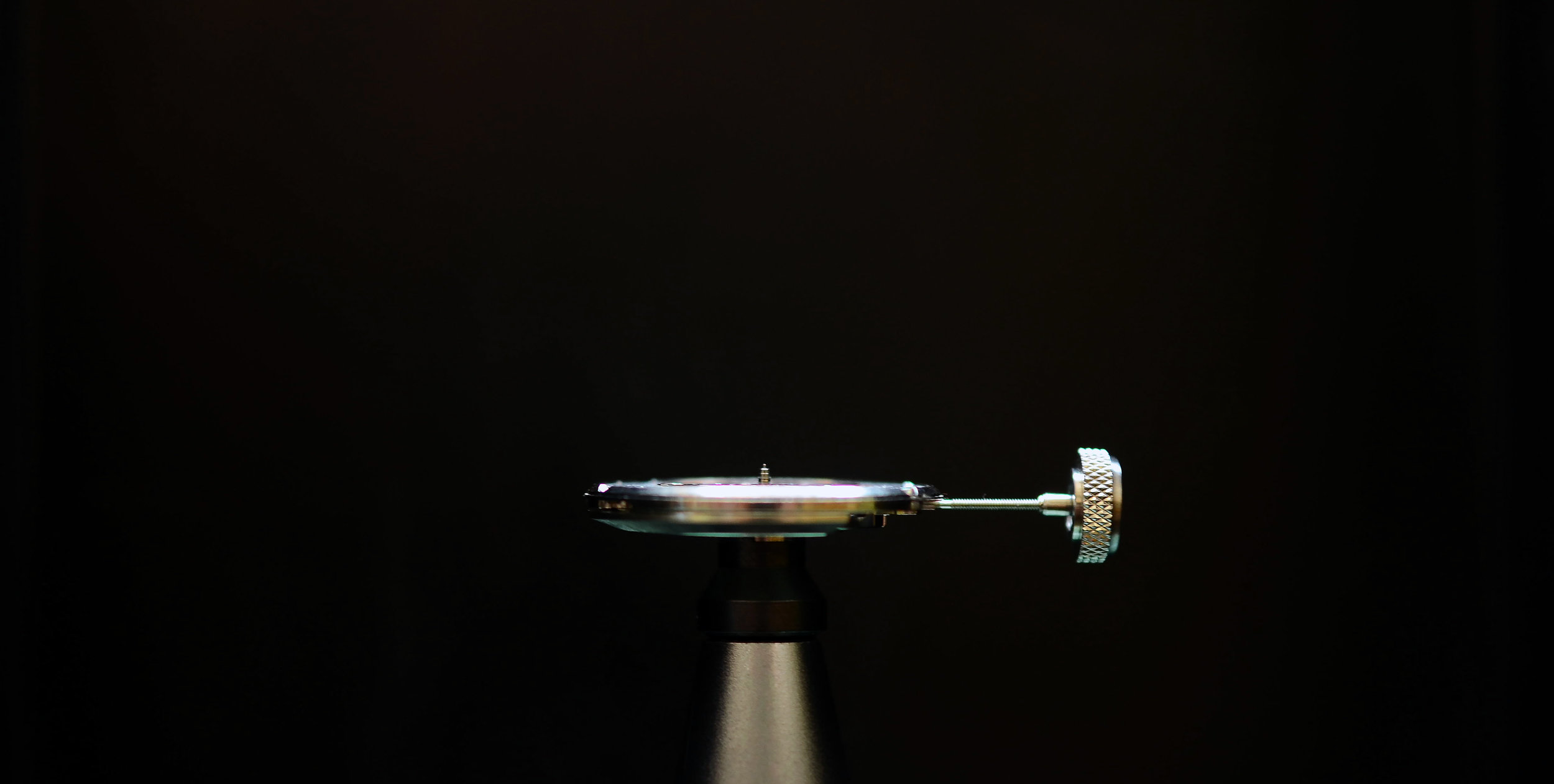

This meant that Omega (who was prototyping this for more than a year) had to yield to Rolex’s patent on the HEV, but the beastly Ploprof didn’t need some fangled pressure relief valve. These watches needed to withstand not only very high atmospheric pressures, but also withstand or resist helium ingress or the pressure differential inside the watch once you decompressed. To combat this the original Ploprof was machined from stainless steel and had a monocoque case construction, this means there was no caseback, the case was a single block of steel and the movement was loaded through the crystal aperture. A technique used to increase the rigidity of the case and reduce the points of ingress and egress for gases and liquids. High pressure causes deflection and flexure of watches, generally in the center, which means things like crystals and casebacks will flare out and the gasket seating will become compromised. Rigidity is important for reducing this. Next the crystal and crown need to be tackled. For the crown, they used a screw down locking mechanism. It’s a bit different from the screw down crowns of today, a nut screws in (or out) the square crown, which locked it into place. There were a series of washers and gaskets which were compressed and created a redundant waterproofing system, which today we see multiple redundancies on advanced crown and tubes. The crystal is more fun. They knew that helium would bypass the gasket no matter what they did, but they also had to make a watch water resistant to great depth. They used a massively thick crystal and a big gasket, then, on top of that, a screw down ring compressed and locked the crystal into place and ensuring engagement with the gasket (as well as driving the rest of the watch components into alignment). This way, in the instance of a case popping pressure incident, the crown is locked and the crystal is locked. The inside of the watch will still remain pressurized, but unscrewing the crown or simply letting it sit would allow it to attenuate, albeit more slowly. And thus, the beastly Ploprof was created. A watch milled from a giant block of steel, with a specialized crown lock and a hefty, stepped crystal with its on steel washer-bolt to keep it locked down. The bezel is thick and easily manipulated through a wet or dry suit, many dive watches featured a unidirectional ratcheting bezel (this way your dive could only be shortened and not accidentally extended) but the Ploprof created a redundant lock for the bezel. It’s bidirectional, but it’s only operational when the large bezel lock button is completely depressed. It’s a 2 hand operation and the chance of some sort of accidental bump that could somehow compress the button and turn the bezel is virtually zero. From necessity rises function and from functionality rises design. The Ploprof is a hulking, Millenium Falcon shaped watch that is meant for great depths, saturation diving, and easy operation with a neoprene coated hand. There is something very cool about the brutal design of it, which, it is certainly polarizing in the sea of watches we’re exposed to today, but that’s because the Ploprof was shaped through a gauntlet of unique demands. So how does the modern one stack up?

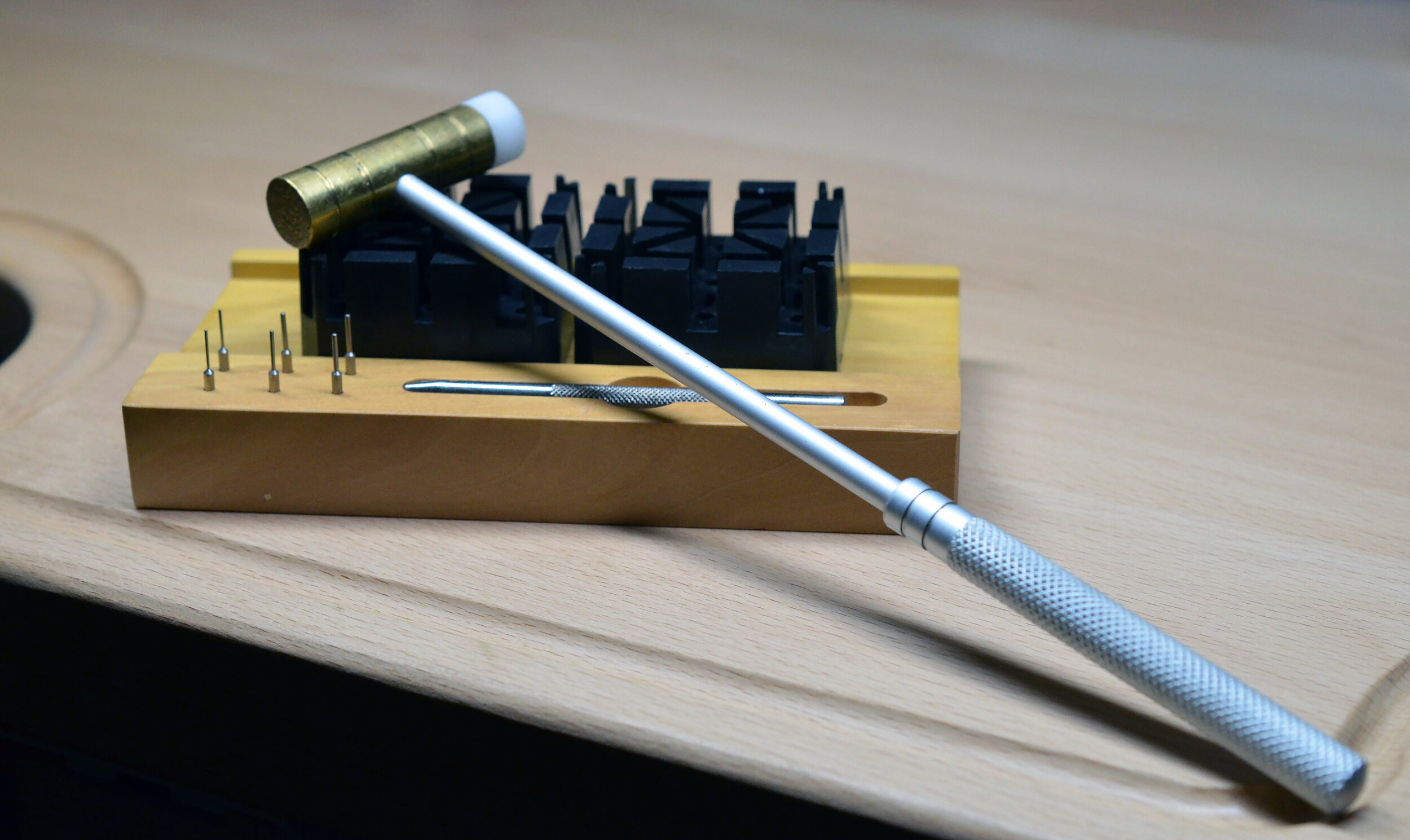

Cross section diagrams of the original Ploprof.

I was fortunate enough to snag a display model for 70% off of MSRP. The newer versions were made in steel and titanium, this is the titanium version. Even though my wrists are tiny, as a watch enthusiast and watchmaker interested in the evolution of dive watches, I’d always wanted a Ploprof but kind of resigned to it being out of budget. The MSRP on this one is in the ballpark of $12,000 (upon looking, the remaining inventory is now priced at $13,800), which I personally believe to be a bit too much. Though, perhaps the reasons that make me feel that way wont be as important to you, regardless, this version is now discontinued and has been replaced with one that draws more from the original - with the exception of a strangely awful blue colorway, this would have been a cool watch in the traditional colors. Lets explore what’s working and what isn’t. When I think of a watch, I break it into its respective components, each has value and interplay that contribute to the whole picture and value. Those components are: the case, the dial & hands, the movement, and the bracelet. I consider each on its grade or quality which is derived from how it’s manufactured, as different manufacturing techniques have goals and constraints.

DIAL & HANDS

The dial, hands and bezel are some of my favorite things about this watch. While I’m not entirely sure if this dial is made of ceramic, (Omega did produce many ceramic dials) it matches the luster and tone of the ceramic bezel insert perfectly. This creates a virtually seamless flow from dial to bezel, when the materials are the same, the way they reflect light is very harmonious, this unifies the watch in a more subtle but tasty way. The diamond cut and applied Omega and logo sit glistening atop the already polished dial, capturing photons and your attention. While the logo and Omega text are diamond cut and flat, this creates a uniformly reflective plane that captures light in a distinct way, the indices, unfortunately are not manufactured this way. Each indice, while supporting Omega’s impressive lume, is likely stamped then hand polished as they all have rounded edges. The round edges of the indices reflect light much differently than the flat diamond cut of the logo and reduce the design cohesion through small elements like this. Having flat diamond cut indices may give the watch more “bling” factor, as the rounded profiles soften the reflections, it also feels like a choice that doesn’t have a very good explanation as to why. I would have preferred all the indices to match the logo in the flat diamond cut, just as the ceramic (presumably) dial and bezel insert match, these elements matching would be a very nice touch.

Onto the hands and colors. The hand set is mostly in keeping with the original, though the hour hand is painted and the minute hand is lightly blasted metal which is then ion plated orange. The seconds hand is again painted, with a painted orange tip. Obviously, orange is the accent color here and we see it in the hand set, the dial’s Seamaster text, the orange pip on the bezel insert and finally, the bezel lock button. This is another unfortunate design cohesion miss. In the world of colors, an opaque paint will never match an ion plated metal, just by virtue of how light and pigments work. This means that the minute hand stands out as being a different shade from the painted tip of seconds hand, the bezel pip, and the printed Seamaster text. While the same color code could have been chosen, the result will never be a clean match, even the bezel lock button which is also an ion plated metal appears a slightly darker shade than the hand. While the button and hand are likely the same ion plating color, the flat and reflective nature of how the minute hand was made makes it appear lighter. Next up we have the painted and printed orange elements. For some reason, the Seamaster text on the dial appears darker and slightly more red than the tip of the seconds hand and the bezel pip. I can’t say for sure if it’s actually a different color or an optical illusion elicited by the contrast of the black dial and the slightly different shade of orange from the minute hand, but the result is a mish-mash of oranges tones where the only clear match is between the painted tip of the seconds hand and the center of the bezel insert pip. The theme with the Ploprof seems to be a miss with some of the details that unify a design and make it exceptional, especially at MSRP where you expect these things to be noted. I can understand wanting a raw plated metal look for the minute hand, but one of my pet peeves is slightly mismatched colors or when people use red and orange within the same color theme, it just doesn’t work. If the color matching was better and the indices were the flat diamond cut like the logo, the Ploprof would have a much more fierce and stated design and that’s with only a few very small changes. The lume on the dial, hands, and insert is exceptional and bright, as you would expect from a watch of this caliber; while I’m not a lume fiend I do enjoy the moments when this watch is absolutely glowing.

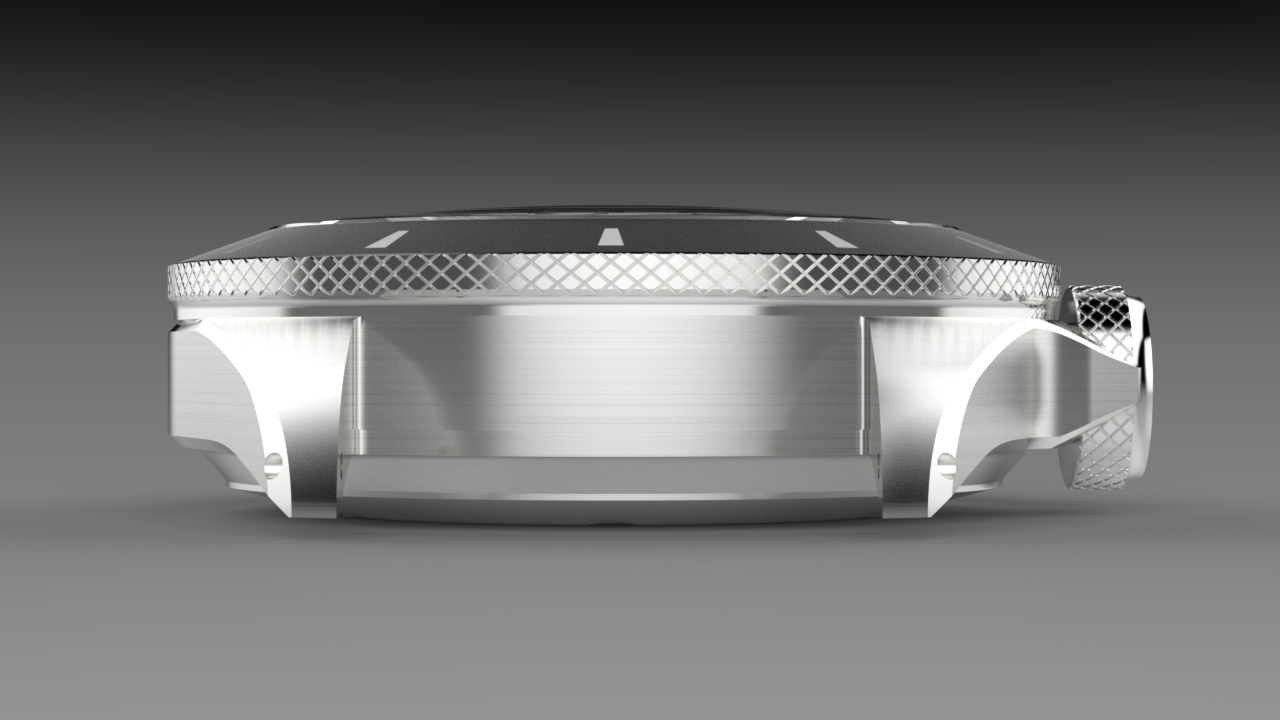

CASE AND BRACELET

The Ploprof has a reputation for being huge and generally unwearable unless you have Hulk sized arms. While it is certainly a substantial watch, most of its heft comes in at how wide it is (remember it’s asymmetrical with a large crown and guard) and its thickness. The secret in the Ploprof’s wearability is the fact that underneath it’s weapon-esque design, it’s a cushion case. The mounting for the strap is recessed further into the case and the result is a “lug to lug” (it’s lugless but you know what I mean) length that is virtually the same as a Rolex Datejust or the Omega Globemaster, two watches that are synonymous with being very wearable and very much in the middle of the road in terms of dimensions. Speaking of optical illusions, this is probably the greatest optical illusion of the watch, hearing that it has the same lug to lug as a Datejust seems rather inconceivable, until you either put the watches side by side or mount the Ploprof on your wrist. It certainly dominates that space, but not in a way that it’s particularly unwearable. Though, the only long sleeves I’d wear it with are the long sleeves of a wetsuit as its abject thickness will be an absolute impasse for sleeves.

The weight is another point of contention, with the titanium version it certainly becomes manageable - it’s a little shocking as the titanium tricks your expectations upon first holding the watch. The stainless steel version is very much the opposite, it’s a heavy, and noticeably so, watch. Which for a watch that’s already peculiar, polarizing, and fraught with stereotypes/misconceptions, the steel version definitely adds weight into the list of things that would make it “a watch for people with Hulk wrists”. Titanium makes it much more wearable and I do personally enjoy the soft hue of titanium in this execution. Speaking of execution, however, case finishing is another point of oversight. The Ploprof’s case features light circular brushing on the top face of it, with vertical brushing on the flanks. The bevel on the top face is also polished, though not in a particularly impressive manner. Another upsetting point of detail loss is this polished bevel. The crown guard continues the bevel of the case but it appears that during manufacturing their polishing process was to work through the mid-cases as a batch then polish the crown guards as their own batch, then assign a crown guard to a case. Why does this matter? With a design like this, if the bevels of the crown guard and case are not cut at the same time, and with the crown guard mounted to the case, they wont match. The angle, the depth, it’s mismatched and the polished line that circumnavigates the case is abruptly broken when it confronts the crown guard which has a bevel that’s a different angle, depth, and does not match the bevel of the mid case. I’m not sure I’ve seen a single modern Ploprof where the bevels are paired. This is another very disappointing oversight, especially since the finishing isn’t complex or done to some exquisite level. It presents itself as an amateurish oversight which traded a small amount of polishing convenience at the factory for a rather glaring inconsistency. And again, I’ll bring up the new MSRP, which after taxes would be close to $15,000 USD. When you have brands like Grand Seiko making titanium watches sing in ways that were previously thought impossible - and for the most part at half the price, it makes you wonder what exactly Omega is charging for because I’ll tell you that it’s not the case finishing. The crown guard is also another disappointment, it’s paired to the crown and as you unscrew the crown it undocks from the case and presents a surplus of wobbly tolerance which deflates some of the muscles of this big bad watch. The crown guard is perhaps one of the more disappointing components of this watch, the tactility is loose and floppy when unscrewed and the finishing is such a glaring mismatch you have to wonder how it got okayed, but it did. If I were running Omega’s production/manufacturing, I certainly would ensure that things like the inconsistent bevel on the crown guard and the unimpressive tactility of it were rectified for a watch of this presumed caliber. It’s a big over-engineered watch that was designed to brute force the problems of yesteryear, with modern manufacturing materials and techniques, no parts of it should feel floppy and given the modern state of saturation diving this is still a luxury item - which means the finishing should be exceptional.

The case also features a HEV, which is kind of funny given the history of the watch. It also has a display caseback to show off the coaxial movement - and adds additional points of water ingress at the point of the caseback threads and crystal gasket. The thickness of the original design was in part due to a lack of modern materials and techniques, including the HEV, which begs the question - does the Ploprof still need to be so thick? Personally, I think the idea of the Ploprof made into a slimmer watch, while maintaining its aesthetic would be quite tantalizing. Sort of like a Safari modified Porsche. Is there something about its large and bulky disposition that evokes emotion? Absolutely, but we’ve introduced mechanisms where the thickness is no longer a functional aspect as much as it is a design choice.

The bracelet and clasp are surprising on this watch, the clasp is easily one of the best clasps I have ever encountered - and you’ll often find owners praising this clasp. It’s thick, thicker than my Calamity dive watch or even any of my Hellcats, which would make it unsuitable on a thinner watch, but the thick clasp of the Ploprof acts as a counterweight and makes sense. For all the hard angled edges of the watch, the clasp is very smooth. It feels good to touch and operate, the tactility is great and the on-the-fly microadjust works well to cinch the watch onto your wrist and readjust it to a neoprene wetsuit without fuss - more colloquially it’s great for letting your friends try it on, even with disparate wrist sizes. And if a ratcheting OTF adjustment isn’t enough, it also has a dive extension folded up within it. The whole system works flawlessly, but not only does it work flawlessly, it looks good and the tactility of it makes it enjoyable to operate. I suspect the person that designed the clasp, was not the person that designed the watch. The sharkmesh band is polished titanium which gives it good wrist feel. Most sharkmesh, while looking cool, in my experience becomes a hair pulling discomfort. The wide and polished links on this one banish the hair pulling and make it an absolute joy to wear - once you size it. Sizing is unceremonious and permanent. You’ll need to bust out the nippers and cut through the individually polished rows of titanium links until you’ve irreversibly sized it to your wrist. Which is fine, but it does feel wrong lopping off links on something so nice and I am a big fan of making things reversible. The bracelet pairs unceremoniously to the case with a springbar, which just feels a little rudimentary. If I designed, or redesigned this, another change I would maker here would be a machined titanium block or endlink with an integrated pushbutton release that fits seamlessly with the cutouts in the case. It’s an expensive watch without many design choices that screamed “above and beyond” but rather doing the bare minimum or “a little extra”. Machined integrated endlinks with a button release would be a very nice touch on this watch, working with the retro-futuristic aesthetic of space-chic and docking components. It would also be a premium feature on a watch that, to be honest, feels premium but doesn’t have any really stand out features (besides its unmistakable and polarizing design).

MOVEMENT

Omega Caliber 8912

With its supple and large jewels, sunburst côtes de Genève

Inside is the Caliber 8912, one of Omega’s coaxial movements with an independently set hour hand complication. It’s a nice dual barrel movement which in my ownership (of both the Globemaster and Ploprof) have never had any issues with. It looks nice and performs well, I do feel like the independently set hour hand is another kind of weird addition of like, “We have this complication, lets just use this movement as value added!” kind of mentality. It doesn’t make too much sense in the context of the watch, but it’s a nice complication to have which makes setting time slightly easier. My belief is that it’s a holdover from a GMT complication, so it makes changing the time convenient if you travel a lot. The movement is something that I wont comment much on, as Omega can serve you those details. It has good machine finishing, the overall design makes for a good look (I like the large jewels for the barrels), the magnetic resistance and silicon hairsprings make for great updates in everyday use. My only reservations would be with the black plated components and the traveling hour hand as additions that present points of failure. If any of the plated components start to fail or rub with other components, you’ll quickly have a lot of movement contamination necessitating a swift service. The hour hand, I can see the wheel that provides the hour jump failing prematurely if someone uses the complication in an excited or excessive fashion. Personally, I’ve not had such issues and the movements have only ever been reliable and accurate for me.

SUMMARY

The Ploprof is a standout watch and despite its handful of design and manufacturing oversights it achieves something, for better or for worse, that very few watches can achieve. It elicits emotions. Love it or hate it, it’s a watch that begs to be investigated and whether you’re reveling in the bizarre watch or lambasting it, it’s a watch that makes you stop and feel something. Which, to me, this is really the core of what watches are about, enjoying something and feeling some kind of excitement. There is something undeniable about its presence, and that undeniability is worth investigating and learning how to apply to other things.

How does it wear though? I have very small wrists and it’s definitely a big watch, but despite its chonkiness, it wears very well. Since it sits so high off your wrist, it does tend to smash into more walls, knobs and countertops, but my watch seems to not accumulate any meaningful scratches or dings, surprisingly. The left sided crown does reveal that they essentially rotated the movement and flipped a dial around, I find myself rotating the watch 180º to wind and set time since the crown functions are inverted when you operate it on the left, moving it so it’s oriented to the right makes it operable like a normal watch (perhaps another oversight? Should the movement have been redesigned to have an intuitive winding and setting train for LHD?). It’s a watch that certainly announces its presence, to you as you wear it and to others. With Orion, part of the design goal is to make watches that are ergonomic and don’t bother or nag your wrist, the Ploprof is the opposite of this. After a day of wearing it, it certainly lets you know that it’s time to take it off, whereas with an Orion you may forget that you’re wearing it (I do at least). The Seamaster is a strange watch and it certainly has its quirks, which as you know I’d revise, but it’s a watch that’s so unique and weird that is captures some kind of odd lightning in a bottle. I don’t think it makes a compelling argument at MSRP, but pre-owned or significantly discounted it’s easier to forgive some of the aforementioned quirks and oversights. It may be easier to hate than love, but it is a watch that nearly all watch-literati are familiar with and that’s saying something.

Regulating the unregulated

Throughout the microbrand watch space you’ll hear many brands tout that their movements are “regulated”. While this phrase initially strikes confidence that your watch is being adjusted finely and has a closer set of eyes on it, there is much more to this unregulated claim than an un-critical take may lead you to suspect. To break this apart we’re going to need to understand a few things and those things will be, chiefly:

What is regulating a watch?

Why do watches need to be regulated?

What are the industry standards?

Regulating a movement is a “value added” phrase which is challenging for the average watch consumer to verify with the same technical veracity as a watchmaker or technician equipped with proper technique and tools. This is also an unregulated and arbitrary claim, meaning there wont be a legal issue if someone isn’t entirely honest about when and where their movements are regulated or adjusted. The combination of these two things, an unregulated phrase used to imbue value to a product, and a technique that requires specialized tools and some degree of training to interpret the data, means that the average consumer is ill-equipped to challenge the claim a brand will make about the further adjustment of their watch, not only are they ill-equipped to challenge it they are in the dark on how a brand providing additional regulation beyond the factory may in fact, be a hint at subpar quality and cost cutting. Before we get into that, lets understand regulation first.

What is regulation?

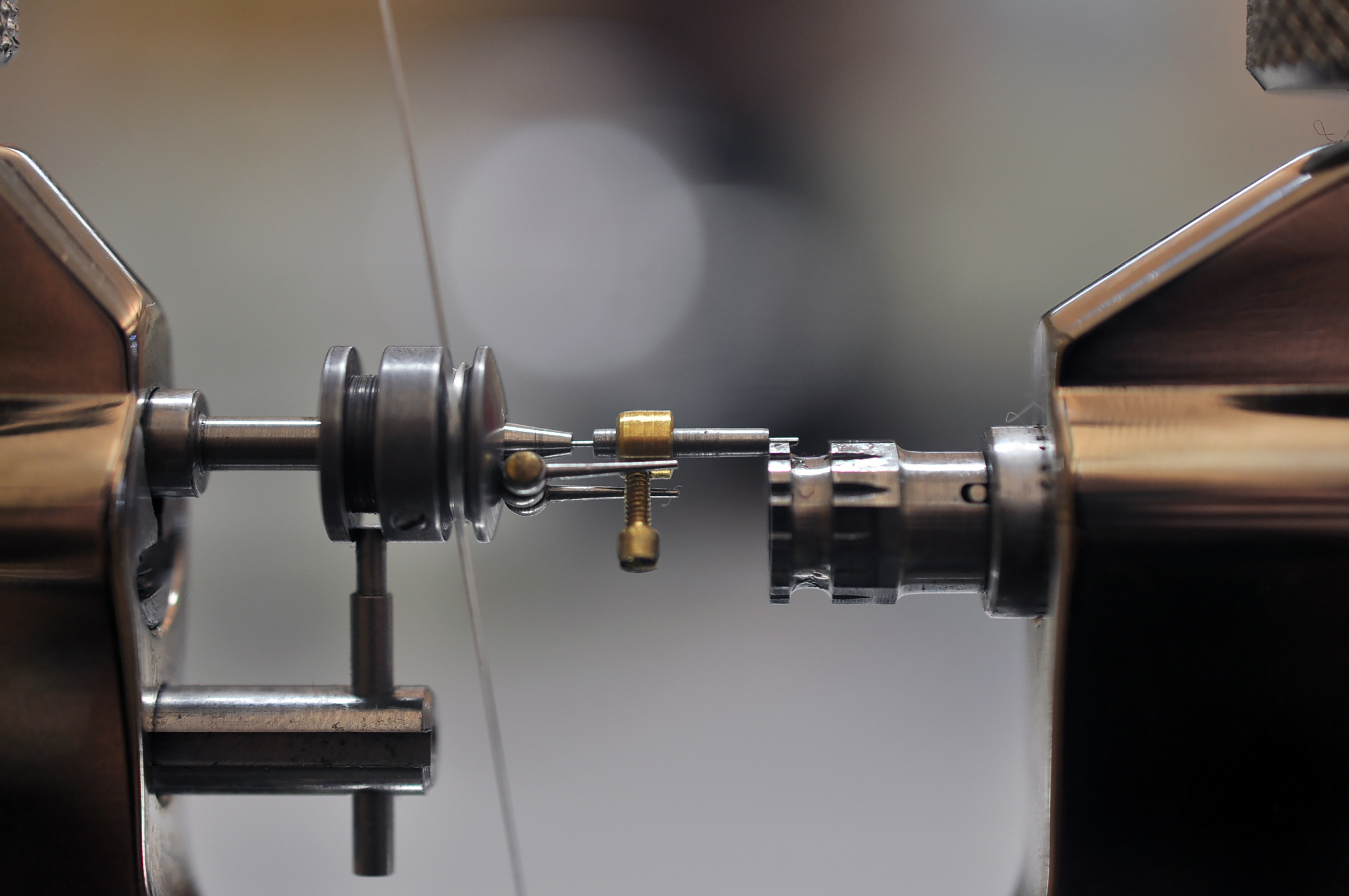

Regulating a movement, in its simplest execution means that the timing rate has been adjusted. This, most commonly is done by changing the effective length of the hairspring by moving the regulating arm along the hairspring. On freesprung balances, that is, movements that do not have regulating pins, the moment of inertia for the balance is changed to alter the rate - this is done by moving weighted screws on the edge of the balance in or out. Much like when you spin around in an office chair, if you stick your arms out you will slow your speed, tuck them in and you will spin faster. Freesprung balances and hairsprings are generally reserved for higher end watches, since the claims of regulation are generally a microbrand phenomena we will focus on movements that use regulating pins. The two minute video below succinctly shows you (in an abbreviated manner) how a regulation may be carried out with such a movement.

So in its simplest terms, it is adjusting the regulating pins or timing screws/nuts to alter the rate. Regulating pins alter the effective length of the hairspring - they are two pins that the hairspring goes between, as the balance oscillates it bounces between them. Making it longer will slow the rate, while shorter will increase the rate. In the video or elsewhere you may have heard of “dial down” or “dial up” perhaps “horizontal and vertical positions”. A watch is a mechanical machine, the tiny pinions, pivots and gears are subject to gravity, friction and other forces that affect how the machine keeps time. A horizontal position would be when the dial is facing up, if you rested the watch on its caseback on your table, it would be in the dial up position. Conversely, if you put it dial down, it would be resting on its crystal. These are the horizontal positions. Watches, generally, are regulated in the dial down position and run better in the horizontal positions. There are a few reasons for this, but it mostly has to do with the pivots of the gears are exposed to less friction in these positions. This reduction in friction means higher amplitude and generally better timekeeping. Amplitude, simply, is the degrees of rotation of the balance wheel. This is used as a proxy for the health of a movement as a watch with higher amplitude generally means more energy is moving through the gear train. If the flow of energy through the gear train is homogeneous and uninterrupted, your timekeeping will also be better. So if you’re timing a watch and have erratic amplitude it would be suggestive of a problem. Stable amplitude is a good sign and amplitude is generally very good in your horizontal positions. The vertical positions would be when the watch is in a position that isn’t flat on a table. Imagine a pocket watch in the pocket of your vest or perhaps when you bring your wrist up to your eyes to check the time - these would be vertical positions. It is normal and expected to see a drop in amplitude in vertical positions when compared to horizontal positions, again, there are many influences but the cardinal influence here is that the surface area that the pivots of the watch movement is exposed to increase. This increase in surface contact increases the friction and consumes some of that energy that would be converted into amplitude.

An example of a Rolex balance with timing screws.

Watchmakers are constantly hunting ways to battle the disturbances of isochronism, which is the ability for the oscillator to maintain the same rate regardless of the amplitude. Which if people pay attention to fancy new materials in watch movements - these are generally things that aid in the battle against those disturbances of isochronism. Many finely made and adjusted movements can do very well in the various positions but the reality is that change in amplitude affects the rate. In lower cost or older movements, those changes may be more noticeable. Again, this is something a watchmaker knows and expects. Regulating a watch means anticipating this. Remember amplitude affecting rate as well as horizontal and vertical positions affecting rate and amplitude going forward - this is an important principle.

Why do watches need to be regulated?

Movements require regulation for various reasons. When a watch is first manufactured the balance wheel needs to be trued and poised - microscopic amounts of material may need to be removed to ensure the weight is consistent all around the balance - this will affect its rate. The length of the hairspring needs to be perfect or it will not vibrate at the correct rate. Regulating pins may need to be centered, opened or closed. Stud length may need to be adjusted - the list goes on. Once a movement is made and the watch is assembled all the forces of isochronism need to be accounted for and the tolerances of machining come to light. Watches need regulation to keep time, otherwise they lose all utility as a tool and become a meaningless mechanical bauble. The concept of a watch needing to be regulated after it is manufactured and unadjusted is not a hard one to grasp, it is starting from nothing, after all. After being worn, a watch may require additional regulation. Things like impacts, wear and tear, loss of lubrication and simply existing outside of a vacuum and a theoretically perfect world will cause timing metrics to drift. The amount the regulating arm needs to move to create a significant change in timing is a very small amount - often fractions of a millimeter in distance, it shouldn’t be hard to imagine that a life on the wrist may introduce small shocks (even imperceptible to the wearer) that could slowly bump the regulating or stud arm in either direction, causing a not insignificant change in rate. It’s a mechanical machine, metal wears out, lubricants oxidize or disappear - as this happens metal dust appears in the system or tolerances change further, worsening the timepieces ability to carry out its duty. Sometimes age alone is enough to cause lubricants to wither and wear to set in. It’s normal for watches to need adjustment as they are worn or age.

A ruby bushing. The pivot of the wheel goes inside the ruby bushing. You can see the hole on this one is no longer round and there is a groove cut into one side of the jewel. This happens when wear or mis-adjustment causes the wheel to lean and it no longer rotates concentrically. Cutting into the jewel over time.

Watch movements are regulated at the factory. Movement manufacturers sell their movements in tiers of fineness. Each tier of fineness will be accompanied by things like higher grade finishing and timing. The factory will then define standard operating parameters and tolerances for their movements, they often ensure that their stated numbers for things like rate and power reserve have enough of a buffer built in so that the movements they sell can outperform their stated tolerances on performance metrics. This is important.

What are the industry standards?

For watchmakers and service jobs, the standard for timing and regulating a watch is 5 positions. Dial up, dial down, crown up, crown down, and crown left. The 6th position, crown right, is an awkward position that often has the worst timing metrics and isn’t experienced with reasonable frequency when worn. Some brands include the 6th position. When I timed out and regulated all the SW300s and 2892s for the Calamity, I timed and regulated them to 6 positions. Going back to movement tiers and stated manufacturer tolerances for a moment. Lower grades of movements or large service centers may only time 2 or 3 positions. Since comprehensive timing takes, well, time, a way for them to reduce costs is to reduce the time spent timing and adjusting a movement. If they’re only timing for 3 positions and their tolerances only account for those positions, you’re omitting a large potential data set of rate averages. Still, money is king. As the grade of the movement increases you may see the number of positions timed in, increase to 4 or 5. Additionally, these factories sort their balance wheels. Some balance wheels just keep better time. The best ones will be reserved for chronometer grade or top grade which undergo the most comprehensive timing tests and have the tightest tolerances. That’s why these also cost the most. Though, when you see a brand slyly remark that “their movement is keeping COSC time” it is a nefarious remark designed to exploit ignorance on what timing and regulating is. The COSC chronometer tests are extensive, 5 positions over 15 days at various temperatures and conditions. COSC is also an independent organization, such independence removes a conflict of interest and bias. I also have serious doubt about brands that make dubious claims would take 3 weeks time (of working days) to time their watches and not want something more objective to show for it. There is another timing metric not yet touched on called ‘delta’. The delta is the difference between your fastest and slowest positions. The delta tells a different picture than the average rate. You can imagine it’s possible to average 5 huge numbers to achieve 1 small number, this could be a way of saying “your average rate is good!” when in reality, the rate of any one position could be massively out of tolerance. This is where delta comes in, the average rate is only meaningful if the delta is small. The smaller the delta, the more impressive the timekeeping.

With all this information you may start to see where I’m going. Are brands providing timing sheets? Is this evidence of regulation or simply timing? Was it only 1 position? Perhaps 2 or 3? Again, this omits a significant amount of the data. Full wind & half wind?

A Rolex Timing Sheet

You can see the 5 positions here as well as slots for amplitude and rate at fully wound and at half wind. A comprehensive timing test includes half-wind metrics to ensure isochronism is not sufficiently disturbed when the mainspring is not fully wound. Since at full wind, the mainspring will deliver the highest amplitude and best timing - if a watch is incapable of providing stable timing at half-wind, it would fail this timing test. Additionally, you can see spaces for the rate to be averaged. When a watch completes its timing test, the average rate (of the 5 positions, or 5 positions at full wind and half wind) would be given to the customer as the rate of their watch.

Many people may be familiar with the given tolerances for movements like Seiko’s NHxx family or the Miyota 9000 family. Perhaps even the different grades of entry level ETA and Sellita movements. Now, remember when I said they add a buffer to stated tolerances, especially on lower cost movements? This is where the whole “We regulate our movements!” craze came from. Seiko states the tolerance for most of their NH movements to be -20 to +40 seconds a day. Miyota states -10 to +30. Now, I’ve dealt with hundreds, if not thousands of these movements and they are never this bad as a batch. Sure, every now and then you might get a bad one, but for me, problematic movements, we’re talking outside of 30s/d has been less than 1%. I’ve found that Seiko movements dont have as great rates as the Miyotas but even more specifically, Seiko NH movements have large poise errors and big deltas where the Miyotas do not. Additionally, I’ve found that many of my Miyota movements come to me keeping +5 to +10s/d accuracy. Which is spectacular. I went through, timed them all and discovered the rates were so good that I (within reason) couldn’t improve them. When you adjust the regulating arm on these watches it adjusts the rate of all positions. Omitting positions can be either a factory simply selling a lower tier movement, or a company intentionally hiding a significant percentage of data. If you, for example, only regulate it in dial down it is not hard to get it to 0 s/d. What did that do to the other positions? The horizontal positions usually mirror each other in metrics, so two positions, dial up and dial down, are not sufficient for a representation of the timekeeping of a movement. Going back you may recall when I mentioned the poise of a balance wheel - many of these more affordable movements may regulate a movement around a heavy spot in the balance. This means one position will stick out like a sore thumb, either much faster or slower than the rest of the positions, the opposite position of the poise error will have the inverse reading. For example, a poorly poised balance may show up as a very fast rate in the crown at 6:00 position, with the crown at 12:00, if it is truly a poise error, would read as the slowest position. Now if you’re timing in 3 positions, dial up, dial down and crown left, in this scenario, you’ve very conveniently hidden a poise error that would not only alter your average rate, but give you a massive delta. The only way to correct a poise error is to remove the balance from the watch, identify the heavy spot, and cut away a nearly microscopic amount of metal, reinstall it and re-test it (there are some balances with weights that you can use to adjust poise, but we generally don’t see these in microbrands). Poising a balance is a very delicate operation. Manipulating the escapement of the watch, that is things like the balance, hairspring, pallet fork and escape wheel, require great skill and many, many hours of training. Poising the balances of a Miyota, Seiko or entry level ETAs or Sellitas isn’t a very sustainable practice on a large scale - and I would know, I’ve done it. You can get the Miyotas and ETAs/Sellitas to really sing and have incredible rates if you’re determined, but the truth is, if you’re getting them factory fresh they’re already way better than their tolerances would suggest and barring advanced timing techniques that take considerable skill and time, they really wouldn’t see any, or much, benefit from regulating.

There are multiple ways to check the poise of balances, this is one. On razor polished stainless steel or ruby jaws on a perfectly leveled special vise you rest the balance staff and very gently, with a puff of air or a tickle from a cat whisker you roll the balance. It should stop without rolling to a heavy spot. Check multiple times and locations to see if it rolls towards a heavy spot.

I think that there is some hysteria around seeing the tech sheets from the movement brands then assuming that all their movements are going to come out running -10 to +30, but they don’t and brands know this and it’s really easy to say that you were the one that kindly regulated it. Unless, the movements actually do need regulation, which raises more questions.

In the watch industry, movement purchasing can often represent the bulk of the cost of the watch batch. The factories that produce movements generally want high minimum order quantities before bulk discounts kick in. In many places, watch factories (the ones making cases, bracelets, dials, etc) may have a deal with a movement factory to purchase, say, 10,000 movements which get sold at a very nice discount, they’re able to pass that onto their clientele (with a markup of course) but in the end it still saves a microbrand from spending the thousands extra from an order on the scale of hundreds of units (or less). That is, however, in an ideal and perfectly honest world, which this is not. The reality of movements, especially in demand models or more expensive ones is that refurbished units make their way back into circulation frequently. Unscrupulous or aloof brand owners may find themselves looking for the best possible deal on movements and this is where refurbs come in.

The macro brands make watches in batches of thousands. They often have designs and releases planned years in advance. Sometimes their designs simply suck, perhaps tastes change or there’s a bump in the market. Doesn’t matter. Sometimes the result is watches that are already assembled sit, unsold, for years. Assembly houses and distribution centers all cost something and these big brands often find themselves losing more than the watch may be worth if it’s not selling for whatever reason. To recoup costs, they may find a movement broker, a professional who sells and resells movements to move their idle inventory. These people are happy to sell at low prices and low minimum order quantities. Bear in mind, these are also movements that have been presumably sitting for years and now they’re being quite literally ripped out of watches by a company looking to save as much money as possible to pass onto the next person.

An example of testing a “vertical” position.

As I mentioned earlier, a watch sitting for a long time is enough to, in many cases, warrant regulation if not an outright service. A movement brokers job is to sell movements. Not service them. Not inspect them. Just sell them. This broker is happy to sell to factories and individuals alike - these are both entities interested in saving money. This is how movements that aren’t fresh enter circulation, while some of these movements have been cared for and properly decased and perhaps serviced, just as many, if not more are neglected. The result is many brands, perhaps to their knowledge or not, are now selling used or, if not quite used then old stock, movements as new and these movements will often have abysmal timing and strange defects, this is simply by virtue of rough and hasty handling, aging on a shelf somewhere, an unskilled service or perhaps no service at all.

Then imagine you get your batch of movements and the timing is closer to what that tech sheet from the factory says. You see 30 or 40 seconds a day and it confirms some suspicion or bias that the tolerance sheet was simply accurate and that’s how these movements perform. So you get to work regulating them and you pass that onto your customer, that your movements were loving regulated and brought into much tighter tolerances than when they arrived. Other brands see this and buy a Chinese timegrapher and printer and start printing out timing sheets, or maybe just writing on a card in 3 positions, but their movements are fresh and don’t need to be regulated - not wanting to seem like a slacker, they say they regulate them too, surely a card with timing values is enough to convince someone their movement was regulated. Then you have a runaway issue of brands claiming regulation, with little or dubious evidence and perhaps little to no training and what they’re calling regulation is in fact very far from what a watchmaker would call regulation or a timing test. There’s no way to reasonably poise 500 Miyota or Seiko movements, the time cost would be insane, additionally, this is a skill so few people have, generally left to trained watchmakers. I think we can easily rule out that microbrands, with the odd exception of the occasional experiment or observatory submission, are not dynamically poising their watches en masse. Still, we can also assume that many are not doing full timing tests either, let alone power reserve tests (each Calamity I did was timed in 6 positions and had a 3 day timing/power reserve test). The pricing and the language around it speaks volumes.

Part of a correspondence from an undisclosed movement brand - note that the rates & number of positions are mentioned.

And I’m not saying everyone has to regulate or submit all their watches to a timing test, that’s what the factory should be doing. You should presumably have 1) the movement factory providing its checks then 2) the assembly house or watch factory providing its checks and finally 3) the brands final QC and checks which should include simple timing, which as I hope you can see now, timing a watch is different than regulating it or having a full timing test. If somehow, you, as a brand, are ending up with movements and watches that after multiple presumed steps of QC and adjustment are still failing or performing so poorly you need to intervene, it may be time to start asking about the provenance of your movements. Sometimes its an active cost cutting decision, sometimes someone in the chain tricks you and you have no idea.

Regulating as a marketing phrase and value added proposition in the microbrand space, for me, raises more questions than it answers. I may be a purist but I like when trained and competent people work on my watches and, much like human medicine, we shouldn’t really be intervening needlessly - there should be a sufficiently good reason. I purposely became a certified watchmaker to understand these things at a foundational level, I see many brands that have offsite watchmaker support or no watchmaker support making these claims and I hope that I can arm you, the reader, with some critical knowledge as to what regulation is, why it would be needed, and how to ask appropriate questions that may support the veracity of the claims of a presumed timing test carried out on your watch.

To very finely regulate a watch (i.e. poise, escapement and hairspring adjustment) takes considerable time and skill, to the degree you need sufficient training. To generally regulate a watch takes quite a bit less work, this is where I think most of the claims would fall. So I invite you to inquire on the details of regulation. Why is it necessary? What’s the delta? How many positions? Was power reserve checked? What about timing it at half wind? Even the equipment used can have a bearing on it. Any company that is honestly flaunting regulation as a testament to their skill should be happy to share the information with an honestly engaged and curious customer, while I suspect a less than honest company may provide murky and vague answers. So is that brand regulating your watch? Maybe. And maybe it’s for a good reason and maybe it’s for a bad reason.

In summary and using reductive logic we can imagine a few scenarios:

1) A company buys movements directly from the factory. The factory regulates them, provides timing sheets as proof for each movement which is then verified by the purchasing company upon receipt. Any movement outside agreed upon tolerances is returned and replaced under warranty. The customer buying the movements in this case does not need to regulate them, unless they wanted to save money by buying a lower grade timing spec and spend more time personally adjusting them. At which point proof should be readily deliverable of said adjustments.

2) A brand owner buys movements through their watch factory, who then sources them through a broker or the movement factory. This scenario is like the first one with extra steps. There are 3 parties now, the party selling the movements, the watch factory building and assembling the watch with said movements, and the brand owner who will eventually receive the watches. In this case, party 1 can either be the factory or a broker. In which case, the factory will provide timing sheets as proof of performance to their customer, which is, in this case, the watch factory. The brand owner will not see the timing sheets, but they existed and regulation was performed. Now, the factory has to QC and ensure proper functionality after the watches are assembled and before they are sent to their client, the brand owner. This will include timing tests. At this point, the watches have been regulated at least once and checked at least twice. When the owner receives them, they should perform a final QC which would include assessment of the rate. Now repeat this scenario but instead of the watch factory purchasing from a movement factory, they purchased from a broker. The broker might include timing sheets, but they are not obligated to and many times they will not. Quality and performance may not be guaranteed. In the scenario from the broker, there exists the possibility of the movements being in disrepair, in need of service or regulation. At which point, the watch factory should catch that in their QC and there is still the final QC of the brand owner. As movements stray further from service intervals, it is common for their timing to become less stable. This is a scenario in which a final regulation may be warranted and even beneficial, though, it could end up being a band aid on a larger problem.

3) A company buys directly from a broker. Like scenario 1, a company buys movements directly. Brokers, however, are not obligated to provide the same warranties and tolerance adherence as a factory is. There is a very likely chance these could be old stock or otherwise used or refurbished movements. The owner now has movements that do not carry a guarantee of rate and likely did not come with timing sheets to verify the performance of the movement. This has had virtually 0 eyes on it in regards to regulation or QC at this point and all of that will need to be either carried out by the owner or, the assembly house/watch factory if the purchaser of the movements decides to forward them. In this scenario, you can imagine the necessity for a regulation, let alone a full service is probably necessitated (Sometimes brokers deliver great product! Sometimes they don’t, it’s a gamble and with gambles there are no guarantees). A scenario like this is more likely to see or require additional regulation further downstream in the process.

Then, there are the market pressures, where brands see other brands offering something of perceived value so they want to offer it as well. If, however, whatever they’re offering is not only disprovable but in their interest to make said claim, you can see where you may have an issue of runaway claims. Honesty and deception mixing in a market. If the consumer has no way to readily ask for evidence of said claim, how are they able to discern an honest claim from a deceptive one? The intent of this article is to arm you, the reader, with some knowledge to provoke questions that would reveal an honest claim and a deceptive claim. Since stating things like “we regulate our movements” is a vague term that is unregulated, there is little downside to lie about it if your assertions will never be tested - and the liars extoll an additional cost on those who are honest - those who put in the extra time (and time is money) to either correct issues or demonstrate their competency at regulating a movement now are competing with those who do not expend that additional cost yet make the claim they do. A failure to hold claims accountable, will eventually lead us to a market of wondrous and fabulous statements of regulation and intervention and all sorts of rarified horological adjustments that don’t actually mean anything. Which, is why accountability is important, to ensure that we get what we pay for and to ensure that the words that are being used accurately convey the service and product being provided. There are many ways this claim can go, from honest infusion of competent watchmaking, to a lie simply to keep up with those doing the actual work - there is value in people taking time to create a better product but I know, personally, there are many people who have no issue bending words or finding loopholes to make it sound like they’re doing work they never did.

DESIGNING THE HELLCAT

It has now been a few years since the debut of the Hellcat - with a thousand pieces made it marks a good time to take a look back but also step towards new designs. The Hellcat was released after the Calamity. The Calamity helped me find the niche that I originally wanted with Orion. The first model, the Orion 1, used the Seiko NH35 and as a result, dimensions were constrained (and thick). At that time in the watch industry, there was a Miyota 9 series shortage which drove up the prices, it cost virtually the same as the 2824. When starting Orion, money was a serious constraint. While I love the tankiness of the Orion 1 and the models that shared the case platform, it was ultimately a concession I had to make. The early visions were for slim and small watches, which were missing from the modern day watch catalog which was, at the time, enamored with watches well over 40mm.

The Hellcat exists within the context of the Calamity as the development of the Orion design language. There’s an older blog post on designing the Calamity if you want to understand it more, but it stemmed from a dissatisfaction of the bloated, clunk, and comically large dive watches that dominated the landscape at the time. When it was released it was a bit of a feat as one of the thinnest automatic 200m divers on the market. I wanted the feeling and the essence of the Calamity to be felt with the Hellcat, but I didn’t want it to be a “smooth bezel Calamity”. Besides the passion and intrigue that came with the world of horology, part of what drew me to watch design wasn’t exactly the plethora of watches that I loved and wanted to replicate, which seems to be common for many brands, but rather my dissatisfaction with so many available watches. I see many people take design ideas from watches that they like, and to some degree this is normal, but a lot of what Orion is, is the inverse of what is so common. The dissatisfaction with so many offerings scratches at an itch, and that itch is the drive to uncover what is missing and find out why I dislike so many watches. Once that is discovered the goal is to create a watch that doesn’t seem outlandish and foreign (different for the sake of being different) but rather blends in while feeling new, authentic and novel. I do get ideas from existing watches, though at the same time I try to isolate myself from too much watch media so that I’m not influenced too strongly, perhaps on a subconscious level. Many people like to guess or state where I got perceived design cues from - for the Hellcat, which, to date, nobody has ever accurately guessed the model or even brand. No, it’s not the Railmaster, and if you look critically at each component (case, dial, hands) you will see they are all very different with similarities ending with things like the dial crosshair or the fact that Orion and Omega both start with the letter ‘O’.

Case design is important to me, it is, after all, the way the machine interfaces with your body. This, with many brands, is a source of my dissatisfaction. A combination of being sensitive to the things I wear and having small wrists, many modern watches simply do not feel good. Even if they appear to have modest dimensions, they can just be a jarring interface with your wrist. The Nomos Tangente, a beautiful watch, springs to mind. It’s wonderfully thin but the case and lugs are flat, existing in a single plane, which creates harsh lever like angles once you have it cinched down with a strap. The Tudor Black Bay is another, with a case so slab sided and lugs so pointy it can’t help but be awkwardly top heavy (fortunately Rolex has recognized this and improved it significantly on subsequent models). While there are countless examples, and no doubt case design has improved in the years since the release of the Hellcat, it still bears recounting. Many cases still suffer from neglect, with design focus being solely on the dial and maybe the hands. If a case isn’t awkwardly designed, it’s painfully generic (either lacking in imagination or quite literally a generic catalog case), if it’s neither of those there’s a good chance it’s a confusing amalgam of features that someone did well only to be reconstructed in a way that makes less sense. Now, I’m not hating on all watches, there are many exceptionally designed watches, but the large majority of watches, just aren’t for me.

There should be a flow from the case out through the bracelet that accommodates the wrist and conforms to it, not battle with it.

So how did I integrate this into the Hellcat? Firstly, thinness is important. It stops the watch from being top heavy. A top heavy watch will pull on one side of the wrist, having a tendency to flop or hang out in an awkward spot. Balancing the watch on the wrist helps it to not announce its presence, I enjoy a watch that you forget that you’re wearing. Thin watches also slide under the cuff, an overused saying for sure, but fewer snags on sleeves and things in the world help keep the immersion of the feeling that there’s nothing on the wrist. Thinner and less obtuse cases also help keep the watch safer from impacts. As you recall the example with the Nomos, thinness is not the ultimate factor in comfort and ergonomic design, it’s a small part of a suite of features. Gently curving lugs are another part of that, if they curve too aggressively they’ll exclude larger wrists, if they don’t curve enough it creates that awkward fulcrum with the bracelet or strap and the wrist. Finding the goldilocks of lug downturn is important, unless of course, the goal is to make a specific watch for a specific wrist size. Thinness and a good lug curvature will get you pretty far, next up is case diameter. The Hellcat, like the Calamity, clocks in at 39.5mm. The Calamity has crown guards, a beefier crown, and a bracelet that has larger links and a bit less articulation. While it is slightly bigger, these features all add to perceived size. The mid case on the Calamity, since it accounts for a turning bezel, is thinner and gives it a bit of a race car like feel which pulls the perceived size the other direction, smaller. The Hellcat has done away with the crown guards, implementing a more delicately shaped crown. The bracelet also was newly designed for it - unlike the Orion 1 which had male end links, the Hellcat has female end links. Each link is not only exceptionally thin but short as well. Given that they’re maybe, 75% shorter than the average bracelet link, this increases the points of articulation which translates to matching the curvature of your wrist better than the average bracelet once the bracelet is properly sized. It’s normal for bracelets to flex, keep in mind the wrist is not a perfect cylinder but bracelets are generally constrained by a cylinder like shape. Bracelets with less articulation (think Audemar Piguet Royal Oak) or are more rigid, will flex and eventually bend to conform to your wrist. While it’s totally possible to design a self supporting bracelet without much articulation to be comfortable, there are many bracelets out there that don’t consider this flex or organic shape of the wrist and it creates discomfort. The lack of heft and the veritable articulation of the Hellcat bracelet continue the “doesn’t feel like it’s there” design ethos that is important in the case design. Yes, it may feel a little light and floppy when it’s not on the wrist, but once it’s sized and on your wrist, I promise it’s a different story. There should be a flow from the case out through the bracelet that accommodates the wrist and conforms to it, not battle with it.

The caseback is another key component in how the watch feels on the wrist. The Calamity debuted the curved caseback, which also had a curved sapphire crystal. The Hellcat is all steel. It’s polished not just for aesthetics, but for feel. The polished steel meshes with the wrist in a much more sensational way than brushed or blasted steel may. It’s subtle, but entirely tangible. The Orion constellation emblazoned into the mirror like back is a fun way to help folks brush up on identifying their constellations but also buck some of the more boring trends of caseback branding. The one downside I’ve noticed of this is that it’s susceptible to scratches, especially since many people lay their watch on top of the bracelet. Subsequent casebacks in new models I’ll coat with an anti-scratch PVD coating (like on the anticipated Hellcat 36). The curved caseback is a more organic shape than many of the caseback shapes out there, it matches the shape of the wrist as opposed to digging into it. Combined with the highly articulated bracelet, gentle lug downturn, and thinness of the watch, the result is something that disappears entirely on the wrist. No tugging or pulling, no lugs digging into wrists, no caseback logo stamped into your wrist on a hot day - it’s comfortable, but not in some active way, it’s comfortable in a way where it literally feels like part of your body, it shouldn’t be noticeable. This is why case design is important to me, this is what I felt like was missing in the watch world - options that disappear on your wrist. Too many cloying watches that announce their presence every time you move your hand or arm.

If you look at the technical image at the top of the page, the bottom left view shows a silhouette view. While ergonomics are important, it’s also important to make a watch that looks good - and in my view, that shouldn’t just be from the top down. You should be able to revel in your watch from all angles. Which is another serious point of neglect for many brands. The mid case is made up of parallel sides, they taper inwards, slightly wider at the bottom and thinner at the top where it meets the concave bezel and steps up to the linear dome of the crystal. If you’re not taking an active, mindful account of all of these features it may just appear “natural” or feel “right”. Adding these subtle dimensions and shapes not only makes the case more dynamic and exciting it helps it to feel and look natural on the wrist. The organic world has very little in the way of harsh angles, your body has very few. There should be a mindfulness of the harshness of the angles when creating a watch, adding relief to the angles increases the appeal, the feel, and the comfort. On the other hand, the geological world captures geometric beauty of minerals in an almost mystical way. It’s entirely possible to capture both geometric beauty and introduce the natural flow of the organic world into a watch, and a good watch will do these things. It is, after all, an assortment of metals and minerals designed to rest on your flesh, nature is one of the most powerful designers and we should look to the natural world for help.

Note the sunburst dial radiating out through the dial, onto the bezel flat, then down to the mid case and bracelet

Finishing up the case design, there’s the concave bezel which is a choice that further encourages the dynamic and organic look I was talking about. The Hellcat has few linear and hard surfaces, all with a gentle curve (at least), a linear or flat bezel would be jarringly simplistic, looking out of place and betraying the rest of the case. The bezel has a small flat on top, which on the brushed models has a sunburst brushing pattern which is subtle but it radiates into the brushing of the rest of the case. It’s also an extension of the sunburst pattern on (some of) the dials. In fact, the original models without the sunburst dials were in the blasted cases, which, the tops of the bezels were flat polished. Drastically different feels elicited from simply types of finishing chosen for the same cases. Which gets us to the dial and hands.

When I originally set out to design the Hellcat I had the burgundy dial in mind. The first Sylph had just been a major hit and I thought the Hellcat in burgundy would be, in many ways, its successor. I was a bit surprised when the people who liked the Sylph liked it for more reasons than just the burgundy - not many of the Sylph fans were Hellcat fans. I had created a new watch with an entirely new look and feel, and as a result, a (mostly) entirely new demographic of people would like it. It was, after all, quite different in nearly every way from the Orion 1 case platform and the Sylph dial.

As noted, I wanted this watch to feel like an Orion, in the case that was through using similar lines as the Calamity, similar features, that could easily be called back to Orion design. I also wanted something unique to Orion. Something that would give it undeniable identity. The Orion Classic typeface was designed. An entire alphabet, letters and numbers, created for the Hellcat and subsequent watches and revisions. Crisp serifs, used by the pad printers of the past to increase crispness and the cleanliness of the ink when the pad was lifted from the dial, became a classic “watch” typeface styling. Open numerals, pointed tails, a familiar clarity, and sharp legibility were the driving design forces in the Orion typeface. Unique enough that it should feel novel and refreshing, but again, not so different that it feels outlandish or misplaced. The details of the Hellcat were all intended to be subtle and not overt, a treat for the discerning customer who takes time to notice.

Many of the watches that interested me before starting Orion were vintage watches, largely because they were what met my criteria for wearability and comfort, not to mention the exciting designs. Syringe hands, which are perhaps an evolution of cathedral style hands (which I love), were the choice for the Hellcat. The goal here was to remedy what I felt was the agitation I felt with many (not all) brands execution of syringe hands. Which is that they all felt disproportionate. Other brands often had hands that were seemingly bloated, or perhaps the minute and hour hand were too close in size, or too similar that differentiation of hour and minute at a glance suffered, the list could go on. I wanted the syringe hands to be proportional, but I also wanted to make them easily discernable from each other at a glance - a well designed watch should be highly legible very quickly, a design that forces the wearer to labor over discerning the time is either poorly designed or a concept piece. I wanted to do these things while bringing an elegance to them, soft angles but defined well. The minute hand has an arch in it, which took some work to finally be able to have it a sharp chevron and not muddy looking. The blade of the seconds hand is also much thinner than the industry standard, while some people complain of legibility of the seconds, I do feel it falls in line nicely with the needle section of the hour & minute hands as well as the overall look of the watch.

The dial, even with things like Orion Classic and balanced hands still looked off. Early Hellcat renditions struggled with looking too generic, to combat that a lot of work went into finding the best design for the minute track. Looking back, I recall seeing a good deal of the watch already completed in my mind’s eye but the minute track took many, many iterations to bring the watch together. Below is a gallery of the Hellcat (before it was named the Hellcat) with a basic minute track and some of the crown iterations/studies it went through. It probably had more than a dozen crown versions. Now, you may know why I’m short with people when they ask, “Have you thought of…..” because most likely, I have I thought of it. You can see how with the more Calamity-esque dial that it wasn’t quite as lively or “right” feeling as the Hellcat we eventually landed on.

An early Hellcat with a more plain railroad style minute track and a red colored minute hand chevron.

Above are just a few of the numerous iterations we went through. In ways, designing a watch can be like pouring water down a mountainside and watching the various paths the water takes to go down, then following the best ones - but it requires careful observation of many of the tributaries to find the right ones. Kyle and I spent a considerable amount of time working on the Hellcat and we’re both very proud of the watch. It shines with its comfort and ergonomics, its size and proportions, and just being loaded with details that take a some quiet observation to truly appreciate. Of course, it’s not perfect, but perfection is the end of pursuit. I am excited to produce the Hellcat 36, the even smaller successor to the Hellcat which will take some features and evolve on them, like adding applied indices to the dial, but also finding new ways to express the Orion design language. If you haven’t taken some time to really look at the Hellcat, I invite you to.

The upcoming Hellcat 36 in black mother of pearl

Omega Globemaster VS. Rolex OP36 116000

OMEGA GLOBEMASTER VS. ROLEX OYSTER PERPETUAL 116000

Before Orion and back when watches was just a hobby for me, I enjoyed a small personal collection combined with discovering new watches or maybe trading and flipping to see what may live permanently in my collection, you know, normal watch enthusiast stuff. Something changed once Orion was created, I felt huge guilt wearing any watch that wasn’t my own, this guilt was further expanded when I was setting up my own shop - money for things like vacations and personal pleasures, like my own watch collecting, seemed unimportant when juxtaposed with acquisition of tools and expansion of shop capabilities.

There is a necessity in having an operational shop, especially when it’s directly linked to your income, but on the psychology side of things, that narrative, “all money should go towards the shop/brand!” can quickly shift the healthy balance of work/leisure to nothing but work - especially if watches are both of those things. So, in an attempt to resolve some guilt that may be preventing me from enjoying a large component of what watches & horology has to offer, I’ll be writing this review comparing a new-to-me Omega Globemaster with my Rolex Oyster Perpetual 116000.

The first watch I got and the watch that sent me on this path of horological madness was my great grandfather’s 1955 Omega Constellation. A family heirloom that made its way to me, through good fortune as the other Omegas my great grandfather brought back from Germany over half a century ago were lost in a house fire. I was charged with the Constellation’s care and repair as it needed some love by the time I got it.

Watches are an excellent vessel to store memories and sentiment, the family Constellation is full of that - given its history I have some trepidation in regards to wearing it frequently, its legacy began long before I was alive and although I am continuing the legacy of that watch it doesn’t seem appropriate as a watch to wear frequently. When the Globemaster was announced a few years back I fell in love. With the pie pan dial, star applique, and constellation caseback, it was a clear successor to the Constellation I had inherited. But financially it wasn’t an option for me, I watched the second hand market for years and as my own career stabilized a used one was eventually in the picture. An excellent deal on the two tone Sedna gold model appeared, I had to take it. A continuation of the Constellation from my family but with a history that would be unique to me - so I could wear it without fear of risking family heritage.

At any rate, on to the review. As a watchmaker I view watches as a few discrete components. There are:

Case components, these would be the case, bracelet & crystal.

Dial & hands

Movement

A cohesive watch is mindful of how these are unique and individually designed components but also considers how they come together. You can sometimes see how certain designs favor a watch in a 2D way, which would be thinking of the design as if you were looking down directly at the dial. 2D designed watches generally prioritize the hands & dial while neglecting the case. The original Tudor Black Bay strikes me as one such watch - absolutely gorgeous from the top down, but the case is a slab sided monster and ends up being unbalanced (you see case proportions corrected in the BB58 line). So for this review, I’ll be breaking these two watches into those 3 components and doing a bit of a comparison. As a watchmaker, I suspect some of the criteria that are important to me may be a little different than the average non-watchmaker reviewer. I hope I can offer some insights that allow you to consider and appreciate watches in a different light.

MOVEMENT

At the heart of each watch is its movement, every movement has pros and cons as well as different criteria we can consider. Some of those things are: level of finishing, serviceability, isochronism. Finishing is generally done by machine until you get to independent watchmaking where finishing and certain cuts may be done by hand. Serviceability is important because like all machines, watches need regular maintenance; large brands seek to redirect all servicing back to them so we see more proprietary parts/designs, parts and tool access may be restricted or limited - these things all factor into how much a watch will cost to service and how many people have the proper tools and training to do it. Isochronism is the ability for a movement to keep time and how impervious it is to external forces that would affect timekeeping.

ROLEX 3130

Rolex 3130 courtesy of Rolex.

The 116000 is driven by the Rolex 3130, which is the time only version of the 3135. The main changes being the obvious lack of a date complication and a single jump in the set lever jumper for winding and time setting. Rolex is often scrutinized for its sluggish evolution of its watch designs (wow, they put a jubilee bracelet on a GMT) and while it’s true that they aren’t particularly adventurous when it comes to deviating from their staples, what they have done is developed and designed their movements with the watchmaker in mind. This is a brilliant move by Rolex as it allows them to streamline their service centers and repairs become efficient and quick. Rolex does also unfortunately restrict parts and tool access, though with access to tools, parts and Rolex training these movements become very straightforward to service. A watchmaker joke is that, “In order to assemble a Rolex you just have to put the parts in a bag and shake.” Now, without access to any of the things I mentioned before, it’s likely an independent watchmaker could service it, but there is a good chance some corners would be cut or something could be done improperly. Servicing a Rolex isn’t as ubiquitous as something as a 2824, they aren’t that much more challenging, the things that drive up the cost of a Rolex service are in fact, an individuals access to those things I mentioned earlier - and of course, a more expensive movement is going to be more expensive to service. There are lots of people who can service Rolex, their network of ADs and shops with parts accounts (ORJs and NRJs) are plentiful, there are many independents more than capable as well. This is a watch that, as a watchmaker, I could service completely on my own, though for the average person, it’s important that whoever services your Rolex is familiar and competent with them. Serviceability is good, although restricted, the movement was designed with serviceability in mind. Rolex service starts at $750 with a refinishing and some movement components included - though at the end of the day you’d be lucky getting out for under $1,000. Another tidbit is the screws on Rolex are terrible, chemically hardened and prone to breakage during service. The hardness of chemically hardened screws is not consistent throughout, the outer ‘shell’ is hard and if that becomes compromised the screw will snap. I’m guessing someone did a cost benefit analysis and decided cheaper screws that they could replace with reckless abandon were a better choice than higher quality/more durable ones. Feels weird though when an ETA movement has tougher screws than a Rolex.

The level of finishing on Rolex is good, but not exceptional. The perlage is mediocre with individual pearls(?) being variable in depth and quality but the sunburst grain is crisp and flat - though not a particularly flashy finishing technique. In fact, with the advent of the 3200 series movements, they’ve done away entirely with the perlage, favoring different graining techniques. The 3235 is certainly less flashy, the brushing techniques allow crisp bridges and components - though removal of perlage seems indication enough that perhaps Rolex felt it also wasn’t entirely convincing. There are also a few polished components; the bevels on the bridges, screw heads, and the big rotor axle. The finishing still necessitates some careful handling during a service - and that’s often a barometer of a watchmaker’s skill, if the finishing is marked or marred after a service. Though without a display caseback you don’t really have much of an option when it comes to appreciating the finishing - I believe, however, once price starts getting high enough you should expect higher levels of finishing regardless of if you can see the component or not.

In regards to isochronism the 3130 is pretty good. Rolex generally has shorter pivots on their watches, this mean tighter tolerances and endshakes (endshake is the amount of ‘play’ in the pivots between jewels), a freesprung hairspring (this means timekeeping is more consistent regardless of amplitude), and a laser poised balance with timing screws (timing screws, although more time consuming to adjust, allow for fine regulation). It’s COSC certified, so it has been verified in multiple positions (when people talk about positions, horizontal is flat and the pivots rest on their tips/pinion faces which evenly distributes forces - vertical positions means the pivots are on their sides and weight is distributed unevenly. For these reasons, timekeeping is generally better in horizontal positions) and at different temperatures. Since Rolex has short pivots, the variation between horizontal and vertical positions is low which increases timekeeping stability. The combination of a freesprung hairspring and short pivots gives this watch the ability to be an incredibly accurate and more importantly stable timekeeper. The Parachrom hairspring offers good properties and is an improvement over Elinvar hairsprings, it touts paramagnetic properties - though I’m not sure if it’s completely impervious to magnetic fields. It’s not as good as silicon and regardless of if the hairspring is extremely resistant to magnetism, other components like steel pinions, the escape wheel, and pallet fork are all susceptible to magnetism and often overlooked when talking on the subject - I have another blog post on magnetism if you’re curious. Overall, the 3130 is a stable and accurate timekeeper with great resistance to isochronism - even in the absence of silicon. I’m not an accuracy for my personal watches, but if you’re after something capable of keeping under 5s/d with excellent positional stability the new Rolex movements are very capable.

In summary, the 3130 is an accurate and stable timekeeper with good serviceability (with some limitation). The finishing is adequate though nothing exceptional - perhaps average or below average when compared to other movements around this price point.

OMEGA 8900

Omega 8900 courtesy of Omega